How to Choose the Right Plastic Tubes for Your Manufacturing Needs

In the competitive landscape of modern manufacturing, selecting the appropriate materials is crucial for efficiency and product quality. Among these materials, plastic tubes have gained prominence due to their versatility, lightweight nature, and resistance to corrosion.

According to a recent market analysis by Research and Markets, the global plastic tubing market is expected to reach $8.22 billion by 2027, showcasing a steady growth rate driven by increasing demand across various sectors, including healthcare, automotive, and industrial applications. The benefits of plastic tubes, such as their flexibility, cost-effectiveness, and ease of customization, make them an ideal choice for manufacturers looking to optimize their processes.

This blog will delve into how to choose the right plastic tubes for your specific manufacturing needs, highlighting key considerations and industry best practices.

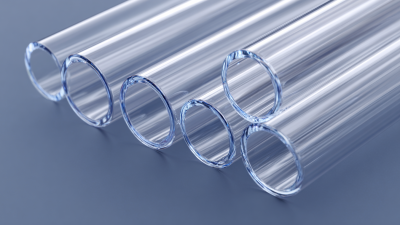

Understanding Different Types of Plastic Tubes for Manufacturing Applications

When selecting the right plastic tubes for manufacturing applications, it's crucial to understand the various types available and their specific characteristics. With the global micro-products market expected to grow from $4.41 billion in 2022 to $9.08 billion by 2029 at a CAGR of 10.8%, the demand for specialized plastic tubes is on the rise. China, having overtaken the U.S. in 2008 as the largest producer of plastic tubing, remains at the forefront of this industry, significantly impacting market dynamics.

**Tip**: Consider the specific application of the plastic tubes. For chemicals, look for high chemical resistance; for food and beverage, ensure compliance with safety standards. The midstream section of the plastic products industry is crucial, as it heavily depends on upstream raw material supply. As the industry evolves, manufacturers should stay updated on the latest material innovations to meet increasing market demands.

The future of the global plastic tubing market looks promising, with projections indicating a market size exceeding $50 billion. Innovations such as bio-based polyethylene (Bio-PE) are paving the way for more sustainable options in packaging, particularly in cosmetics and pharmaceuticals. **Tip**: Explore eco-friendly materials that not only meet performance standards but also align with sustainability goals in your production processes.

Key Factors to Consider When Selecting Plastic Tubes

When selecting plastic tubes for manufacturing needs, several key factors come into play. First, consider the material of the tubes. Common options include PVC, HDPE, and polycarbonate, each offering unique properties such as chemical resistance, flexibility, and strength. Assessing the environment in which the tubes will be used is crucial; for instance, if they are exposed to harsh chemicals, a tube with high chemical resistance should be prioritized.

Another important factor is the diameter and length of the tubes. These dimensions must align with the specifications of your manufacturing process to ensure optimal performance. Additionally, think about the tube's wall thickness, as this can affect both durability and weight. Selecting the right dimension not only enhances functionality but can also lead to cost savings by reducing material waste and ensuring proper flow rates.

Finally, consider any regulatory requirements applicable to your industry. Some sectors demand compliance with specific standards for safety and quality. Ensure that the chosen plastic tubes meet these regulations to avoid future complications. By focusing on material properties, dimensions, and compliance, you can make a more informed decision that aligns with your manufacturing objectives.

| Factor | Description | Common Materials | Applications |

|---|---|---|---|

| Diameter | The inner diameter affects flow rates and pressure. | PVC, Polyethylene | Fluid handling, HVAC systems |

| Wall Thickness | Determines the strength and durability of the tube. | Acrylic, Polycarbonate | Structural components, safety equipment |

| Chemical Resistance | Important for applications involving aggressive substances. | Teflon, Nylon | Chemical processing, laboratory tubes |

| Temperature Tolerance | Maximum and minimum temperatures the tube can withstand. | Polypropylene, PVC | Industrial applications, automotive |

| Flexibility | Determines how easily the tube can bend without breaking. | Silicone, Polyurethane | Medical applications, robotics |

Comparing Material Properties: PVC, Polyethylene, and Polypropylene Tubes

When selecting the right plastic tubes for your manufacturing needs, understanding the material properties of PVC, Polyethylene, and Polypropylene is essential. PVC (Polyvinyl Chloride) is known for its excellent chemical resistance and rigidity, making it suitable for construction and medical applications. According to a report by the Plastics Industry Association, PVC tubes are widely utilized in the healthcare sector, particularly for IV and drainage applications, due to their ability to withstand sterilization processes.

On the other hand, Polyethylene (PE) is well-regarded for its flexibility, transparency, and impact resistance. Its low-density variant (LDPE) offers superior ductility, while high-density polyethylene (HDPE) is preferred for parts requiring high tensile strength. The American Plastics Council highlights that HDPE's lightweight nature and resistance to moisture make it a go-to choice in packaging and food-related applications, where safety and shelf life are critical.

Polypropylene (PP) stands out for its high heat resistance and fatigue strength, making it ideal for applications that involve repeated stress or require autoclaving, such as in laboratory environments. Research from the Polymers Journal notes that polypropylene is increasingly used in manufacturing due to its recyclability and low environmental impact, elevating its status in eco-conscious production processes. Understanding these material properties enables manufacturers to make informed decisions, optimizing their production efficiency and product performance.

Evaluating Tube Dimensions and Their Impact on Performance

When selecting plastic tubes for manufacturing, evaluating tube dimensions is critical, as they directly influence the performance of the final products. According to a report by the Plastics Pipe Institute, the diameter of tubes can significantly affect the flow rates and pressure levels they can withstand. For instance, a tube with a larger diameter will typically support a higher flow rate, making it essential for applications that require robust fluid transport. Conversely, smaller diameter tubes may excel in precision applications where controlling smaller fluid volumes is necessary.

Additionally, the wall thickness of plastic tubes should not be overlooked. Research from the American Society for Testing and Materials indicates that increased wall thickness enhances a tube’s resistance to impact and fatigue, thereby extending its service life in challenging environments. For instance, tubes used in high-pressure systems often require thicker walls to prevent rupture. Meanwhile, the choice of material also plays a vital role; polyethylene tubes can offer flexibility and chemical resistance, while PVC provides strength and durability. Manufacturers need to balance dimensions and materials to optimize performance according to their specific application requirements.

Sourcing Quality Suppliers for Custom Plastic Tubing Solutions

When selecting custom plastic tubing solutions, sourcing quality suppliers is paramount. A recent industry report from Grand View Research indicates that the global plastic tubing market is expected to reach USD 9.06 billion by 2025, growing at a CAGR of 6.1%. This growth is driven by the increasing demand for lightweight materials across various sectors, including automotive and healthcare. Therefore, choosing the right supplier can significantly affect manufacturing efficiency and product quality.

Quality suppliers should provide robust testing and certification for their products. For instance, suppliers that adhere to ISO 9001 standards are recognized for their commitment to quality management principles. Additionally, a survey by Markets and Markets shows that 70% of manufacturers consider supplier reliability as a crucial factor along with product innovation. Thus, engaging with suppliers that not only offer customization options but also demonstrate consistent reliability and innovation is essential for meeting specific manufacturing needs.

Related Posts

-

Exploring the Future of Best Plastic Tubes Technologies in 2025 and How to Leverage Them

-

10 Amazing Toothpaste Tubes You Should Know About

-

The Future of Beauty Innovation with Best Tube Lip Gloss

-

Exploring Sustainable Alternatives to Traditional Lip Balm Tubes for Eco-Friendly Brands

-

The Future of Squeeze Tube Lip Gloss Innovations and Trends

-

Mastering the Art of Tube Cosmetics Application for Flawless Skin