How to Effectively Utilize Label Tube for Your Packaging Needs

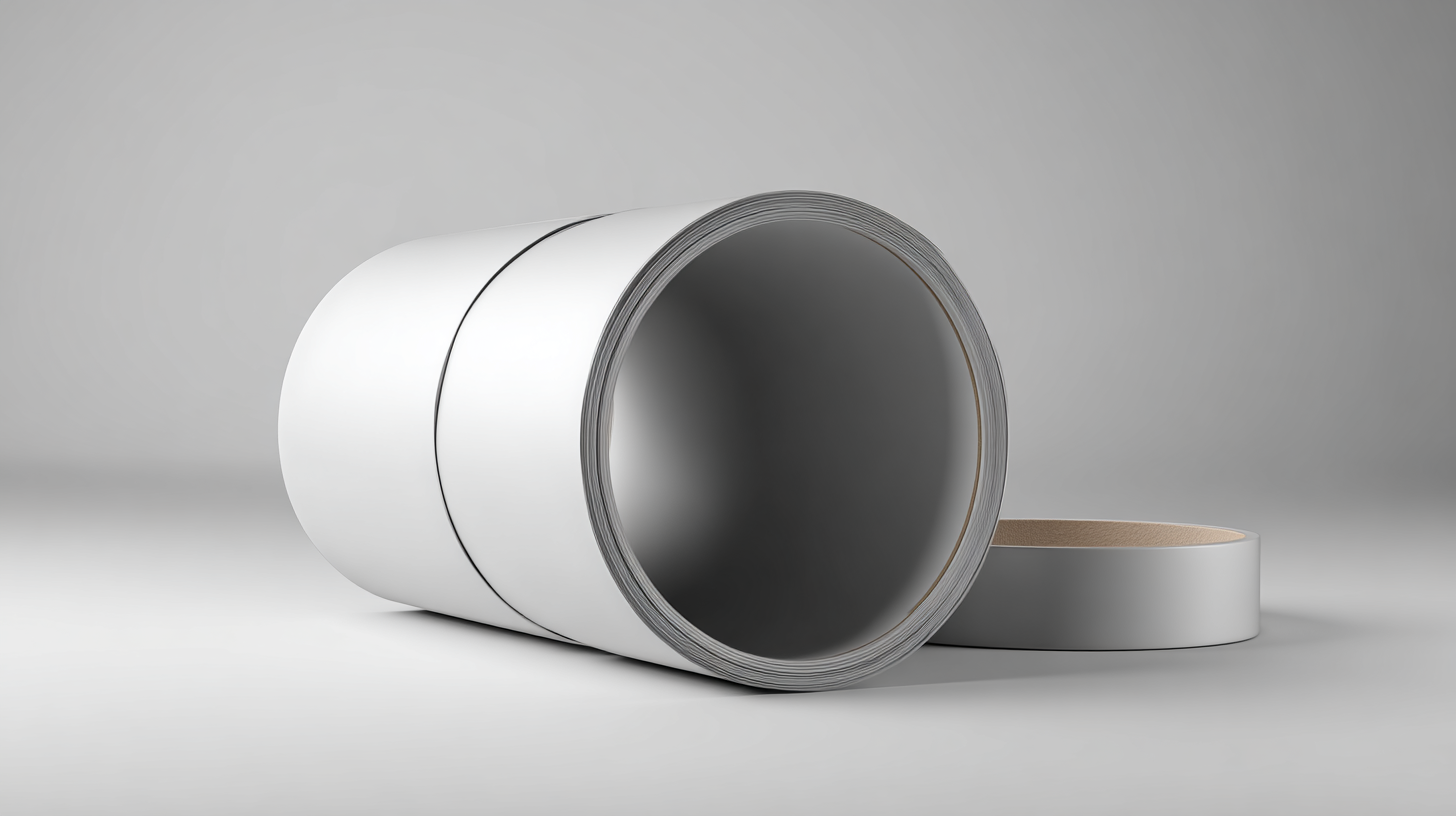

In today's competitive market, the importance of effective packaging cannot be overstated, and one innovative solution that has gained traction is the Label Tube. This versatile packaging option not only enhances product presentation but also provides functional benefits that can cater to various industries. Utilizing Label Tubes correctly can significantly elevate brand perception and improve customer satisfaction by ensuring that products are securely contained and easily identifiable. Whether you are in the cosmetics, food, or pharmaceutical sector, mastering the art of using Label Tubes can streamline your packaging process and strengthen your marketing efforts. In this comprehensive guide, we will explore practical strategies and insightful tips on how to effectively utilize Label Tubes for your packaging needs, ensuring that your products stand out on the shelves while meeting the demands of consumers.

Effective Label Tube Selection for Optimal Packaging Results

When choosing a label tube for your packaging needs, it's crucial to consider several factors to ensure optimal results. Factors such as the material, size, and design of the label tube can significantly impact the overall effectiveness of your packaging. For instance, using a high-quality material not only enhances the aesthetic appeal but also ensures durability during transportation. A well-proportioned size allows for proper fitting of labels, preventing wrinkling or peeling that can detract from your product's presentation.

Tips: When selecting a label tube, always test samples with your labels before finalizing the order. This step helps you gauge how well the labels adhere and how they will look once applied. Additionally, consider the functionality of the label tube; ensure it complements your product's purpose while also being user-friendly for your customers.

Another critical aspect is the design of the label tube itself. A creative design can attract attention on the shelf, but it should also reflect your brand’s identity. Innovative patterns or textures can make a significant difference in consumer engagement.

Tips: Conduct market research to see what designs resonate with your target audience. Collaboration with a designer who understands packaging trends can also lead to a more impactful label tube that stands out in a crowded market.

Understanding the Benefits of Using Label Tubes in Packaging

In the realm of pharmaceutical packaging, the adoption of label tubes has seen significant growth due to their numerous advantages over traditional packaging methods. Label tubes, made from flexible materials, are not only lightweight but also offer robust protection against environmental factors. According to industry reports, the global pharmaceutical packaging market is projected to reach $162 billion by 2024, with innovative packaging solutions like label tubes driving this expansion. Their ability to provide distinct branding opportunities while enhancing product visibility on retail shelves makes label tubes an attractive option for pharmaceutical companies.

Moreover, label tubes are known for their sustainability benefits, which is increasingly crucial as the industry shifts towards eco-friendly practices. With the rise in consumer awareness regarding environmental impact, businesses are adopting solutions that reduce waste, making label tubes a favorable choice. As many companies in the packaging sector are exploring innovative materials, the flexibility of label tubes allows for eco-friendly raw materials such as recycled plastics and biodegradable options to be utilized, aligning with the shifting consumer preferences toward greener products. Thus, the integration of label tubes into pharmaceutical packaging not only addresses functional requirements but also aligns with current market trends focusing on sustainability.

Steps to Customize Your Label Tube for Brand Identity

Customizing your label tube is a crucial step in establishing a strong brand identity. Start by selecting a design that resonates with your target audience. Consider the colors, fonts, and graphics that best reflect the essence of your brand. A well-thought-out design should not only be visually appealing but also evoke the right emotions in consumers. Use elements that tell your brand’s story and communicate its values effectively.

Customizing your label tube is a crucial step in establishing a strong brand identity. Start by selecting a design that resonates with your target audience. Consider the colors, fonts, and graphics that best reflect the essence of your brand. A well-thought-out design should not only be visually appealing but also evoke the right emotions in consumers. Use elements that tell your brand’s story and communicate its values effectively.

Next, pay attention to the material and finish of the label tube. The texture and quality can significantly enhance the overall perception of your product. Options like matte, gloss, or metallic finishes can add an extra layer of sophistication. Additionally, ensure that the labeling conveys essential information such as product details and usage instructions clearly, as this can influence purchasing decisions. With these steps, your label tube will not only stand out on the shelf but also create a lasting impression, reinforcing your brand’s identity in the market.

Maximizing Efficiency: Best Practices for Label Tube Application

In today's fast-paced packaging industry, maximizing efficiency during label tube application can significantly impact a company's bottom line. According to a report by Packaging Efficiency Solutions, companies that streamline their labeling processes can achieve up to 30% reduction in operational costs. This highlights the importance of adopting best practices in label tube utilization to not only save money but also improve throughput and product visibility.

One effective tactic is automating the labeling process. A recent study indicated that automation can elevate labeling speed by 50%, allowing businesses to meet increased demand without sacrificing quality. Implementing advanced labeling machinery helps ensure consistency in application and reduces human error, which is crucial in maintaining compliance with regulatory standards. Additionally, utilizing high-quality materials for labels can enhance durability and readability, contributing to better consumer engagement. By focusing on these best practices, companies can enhance their packaging efficiency and strengthen their market position.

How to Effectively Utilize Label Tube for Your Packaging Needs - Maximizing Efficiency: Best Practices for Label Tube Application

| Dimension | Description | Best Practices | Efficiency Rating |

|---|---|---|---|

| Material Quality | Choose durable materials for longevity. | Test materials before full production. | 85% |

| Label Design | Visual appeal and clear information. | Use A/B testing for designs. | 90% |

| Application Technique | Proper adhesion methods. | Train staff on manual and machine application. | 88% |

| Storage Conditions | Avoid direct sunlight and humidity. | Implement climate control measures. | 75% |

| Regulatory Compliance | Adhere to labeling laws. | Regularly update knowledge on regulations. | 92% |

Common Mistakes to Avoid When Using Label Tubes in Packaging

When utilizing label tubes for packaging, there are common mistakes that can significantly impact the effectiveness of your labeling process. One of the primary errors is neglecting the proper classification of products, which can lead to mislabeling. For items that require specific handling, particularly biohazardous materials, it is crucial to follow stringent labeling standards. Incorrect labels not only compromise safety but can also result in severe consequences, such as medication mix-ups that have been reported in healthcare settings.

Another common pitfall is using inadequate materials for the label tubes themselves. Choosing low-quality tubes can jeopardize the integrity of the labels, making them susceptible to wear and tear. This can be especially problematic in environments where the labels are exposed to various elements or require a high degree of clarity and durability. Proper training for staff involved in the labeling process is essential to avoid such mistakes, ensuring that everyone understands the significance of correct labeling and packaging strategies for different materials.

Related Posts

-

Ultimate Guide to Choosing the Right Cosmetic Packaging for Your Brand

-

Innovative Approaches to Sourcing the Best Tube Cosmetics for Global Markets

-

The Ultimate Guide to Choosing the Best Skin Bottles for Your Global Supply Needs

-

5 Tips for Choosing the Best Lip Gloss Tubes Based on Industry Insights

-

Exploring the Rise of Eco Friendly Cosmetic Packaging at the 138th Canton Fair 2025

-

Ultimate Checklist for Choosing the Best Tube Containers for Your Business