Essential Tips for Choosing the Right Plastic Tubes?

When selecting the right plastic tubes, various factors come into play. Industry expert Dr. Sarah Latham once stated, "Choosing the right plastic tubes can make or break your project." Plastic tubes are versatile, serving numerous applications, from packaging to healthcare. Their varying sizes and materials can greatly influence your decision.

Understanding your needs is crucial. Consider the properties you require, such as durability, flexibility, and chemical resistance. While many options exist, not every plastic tube will meet your demands. A thoughtful choice ensures efficiency and quality in your projects. However, some might overlook the importance of proper sourcing. Skimping on quality can lead to failures, increasing costs in the long run.

Additionally, think about potential environmental impacts. Not all plastic tubes are recyclable. This consideration is often ignored, leading to pollution. Reflecting on these choices highlights the complexity of selecting the right plastic tubes. It’s an important decision that warrants careful thought and attention to detail.

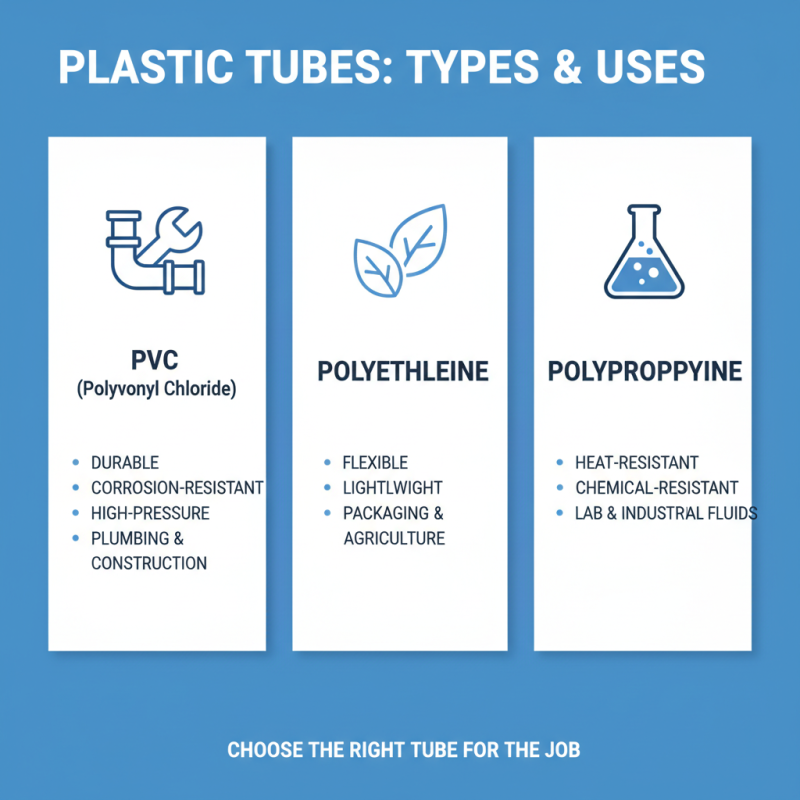

Understanding Different Types of Plastic Tubes and Their Applications

Choosing the right plastic tubes requires understanding their various types and uses. Plastic tubes come in several materials, including PVC, polyethylene, and polypropylene. Each type has unique properties that suit different applications. For example, PVC is often used in plumbing and construction due to its durability. It's resistant to corrosion and can handle high pressure. In contrast, polyethylene is more flexible, making it ideal for packaging and agricultural uses.

According to industry data, the global demand for plastic tubes is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2028. This growth signifies an increasing reliance on versatile materials in different sectors, such as healthcare and food packaging. However, the choice of material can impact performance. For instance, certain plastics may not withstand heat, limiting their applications in medical settings.

Understanding the specific needs of your project is crucial. Consider factors like temperature resistance, chemical compatibility, and application environment. Mistakes in choosing the wrong type can lead to failures and safety issues, particularly in high-stakes industries. Reflecting on these factors can help in selecting the most suitable plastic tube for your application.

Evaluating Material Properties for Optimal Performance and Durability

When selecting plastic tubes, evaluating material properties is crucial. Different plastics offer varying strengths, flexibility, and resistance to chemicals. For instance, polycarbonate is known for its high impact resistance, while PVC is more cost-effective and widely used. According to a recent industry report, over 35% of manufacturers indicate that material choice directly impacts the longevity of their products.

One important tip is to assess the tube's tensile strength. Tubes made from high-density polyethylene (HDPE) are often more robust. They can handle stress better than lower-density options. Consider the environment where the tube will be used. Will it be exposed to UV light? If so, choose a material with UV stabilization.

Testing the thermal properties of materials is also vital. Some plastics disintegrate at high temperatures. On the other hand, others may become too brittle when cold. Always check thermal stability data from reliable sources. It could save you from costly failures. Using a combination of the right materials increases performance and durability significantly. Don't hesitate to run your own tests to ensure that the chosen material lives up to your expectations.

Key Factors to Consider for Size and Dimensions of Plastic Tubes

When selecting plastic tubes, size and dimensions play a crucial role. You must consider the intended application. Are you using these tubes for storage, transportation, or manufacturing? Each use case demands specific dimensions. A tube that is too wide may lead to waste. Conversely, a tube that is too narrow can hinder functionality.

It’s also important to think about the length. The length should accommodate your application without excess. Longer tubes can be cumbersome. They might occupy unnecessary space. Additionally, think about wall thickness. Thicker walls add durability. However, they also increase weight. You must find a balance between sturdiness and efficiency.

Finally, consider the tolerance levels for these tubes. Precision is vital in applications such as fluid transport. A tight fit can prevent leaks. But too tight a tube can cause blockages. Make sure to conduct a trial run with your chosen sizes. Adjustments might be necessary. Remember, perfect dimensions can often lead to unexpected flaws. Reflect on your choices to ensure they meet your specific needs.

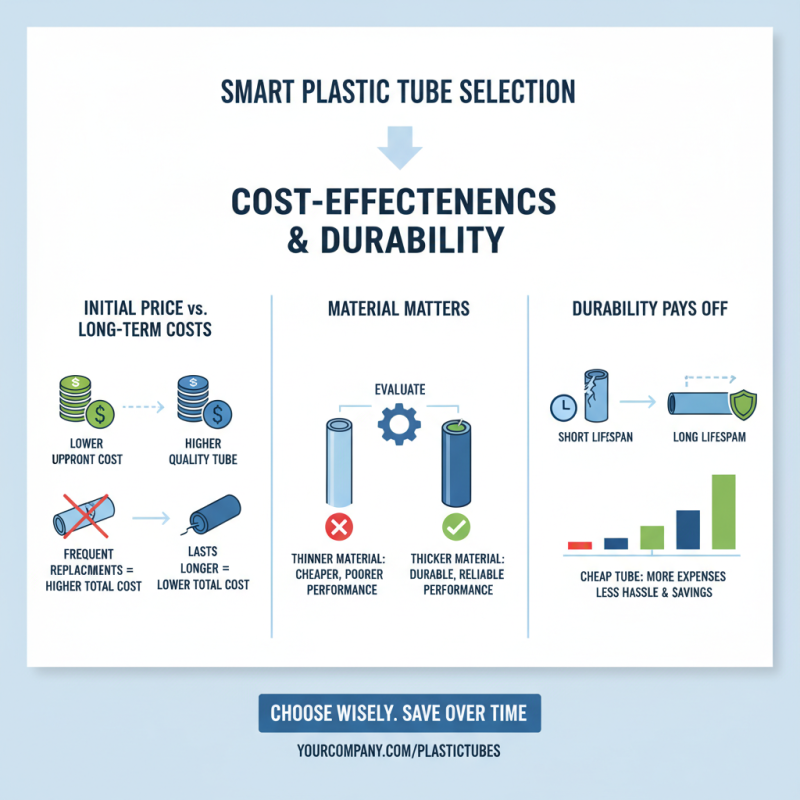

Analyzing Cost-Effectiveness and Budget Constraints in Selection

When selecting the right plastic tubes, cost-effectiveness plays a crucial role. Many buyers focus on the initial price, but long-term costs matter too. A cheaper tube may lead to frequent replacements. This can add up over time. Evaluating materials is essential. Thinner options might save you money initially but can impact performance. Think about durability.

Budget constraints can limit choices, yet making informed decisions is necessary. Consider the specific application of the tubes. For instance, food-grade tubes often cost more. However, using standard ones in that context could result in safety issues. Also, don’t overlook the hidden costs, such as shipping or storage. Sometimes, higher upfront costs lead to greater savings later.

While assessing various suppliers, some might offer tempting deals. Not every option that seems affordable is a wise investment. Inspecting product reviews may help, but remain cautious. Not all feedback reflects actual experiences. Choose wisely, and remember that the right tube balances cost with quality and durability.

Best Practices for Sourcing and Supplier Evaluation for Plastic Tubes

When sourcing plastic tubes, proper supplier evaluation is essential. An effective evaluation process can help ensure consistency and quality. According to a recent industry report, 73% of companies experience issues with tube quality due to inadequate supplier vetting. This highlights the need for thorough assessments.

Start by researching potential suppliers in detail. Look for certifications like ISO 9001. Verify their production capabilities. Some companies might claim high output but lack the infrastructure to deliver. It's crucial to conduct onsite visits if possible. This can expose potential flaws or limitations that aren't apparent in brochures.

After narrowing down suppliers, request samples. Testing the physical properties of the tubes is vital. Factors like tensile strength and flexibility can vary considerably. A supplier might showcase great samples but lack consistency in larger production runs. Be cautious; even slight deviations can lead to significant issues down the line. Consistent evaluations during production can save time and costs in the long run.

Related Posts

-

2025 Top Plastic Tubes Trends and Innovations You Need to Know

-

Exploring the Future of Best Plastic Tubes Technologies in 2025 and How to Leverage Them

-

How to Choose the Right Plastic Tubes for Your Manufacturing Needs

-

What is a Plastic Tube and Its Common Uses?

-

The Versatile World of Plastic Tubes: Innovations and Applications in Everyday Life

-

How to Choose the Right Plastic Tubes for Your Project in 2025